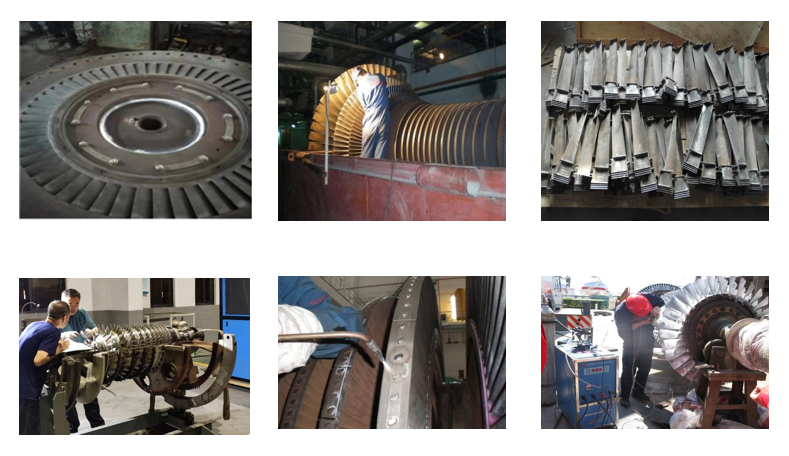

Leveraging our strong customer relationships, we have established in-depth cooperation with China's top laser repair and gas turbine maintenance technology teams. Our advanced repair techniques, such as micro-welding and localized ablation shaping for thermal cracks in cobalt-based alloy nozzles, as well as micro-integral welding for erosion damage on first-stage high-pressure turbine rotor blades made of nickel-based superalloys, are on par with similar technologies from General Electric (GE) in the U.S. and TMU in Germany, while also offering unique advantages. These cutting-edge solutions have enabled numerous customers to efficiently restore critical spare parts and extend their service life, minimizing downtime and reducing operational costs to the greatest extent.

We specialize in the maintenance and repair of the following power equipment:

1. Gas Turbines – Operating temperatures: 1100–1600°C; high-speed, high-load components.

Key components: honeycomb seals, low-pressure nozzles, low-pressure stator blades, turbine disks, high-pressure casings, bearing housings, rotor sealing teeth, nozzle blades, combustion liners, transition pieces, etc.

2. Steam Turbines – Operating temperatures: 500–600°C; rotational speed: 3,000–13,000 rpm.

Services: extending worn rivets, replacing sealing bands, repairing cracks and missing sections in diaphragms, laser additive restoration of fractured shaft ends, replacing damaged seal teeth, repairing cylinder cracks, etc.

3. Exhaust Gas Turbines – Operating temperatures: 800–900°C; rotational speed: 6,000 rpm.

4. Top Gas Recovery Turbines (TRT) – Operating temperature: 200°C; rotational speed: 3,000 rpm.

Services: blade protection and restoration.

5. Compressors – Operating temperatures: ≤200°C; rotational speed: >9,000 rpm.

Services: seal ring restoration, three-dimensional impeller repair, etc.

Amidst the global surge in gas turbine projects and increasing shortages of spare parts, we are actively expanding into international markets. Our technical teams are capable of providing on-site services at customer facilities, significantly reducing downtime and ensuring continuous operations.